Food safety specialists working in the industry know that developing and maintaining a food safety management system requires a significant amount of administrative paperwork. With pressures to go paperless, coupled with increasing regulatory and industry requirements, more and more food manufacturers and importers are turning to food safety software to automate document and record control. Reliable cloud-based applications, available on both PC and tablets, present an affordable option to small food manufacturers and importers.

What Are the Benefits of Food Safety Software Packages?

Food safety experts have long predicted that the use of databases would become essential for managing global food safety risks(1). Information systems in the form of databases are designed to capture, store and retrieve data in a structured fashion. Databases also permit data analysis for tracking and trending. When they are integrated with email, these systems allow for effective and secure communication with stakeholders, thereby enabling decision-making in real-time.

They also permit automated tracking and validation of information, including change control by approved users, through the use of access rules and authenticated signatures. Not only are they readily available and accessible, but also they can be updated and improved easily.

Combined with easy-to-edit document templates that meet international food safety standards, food safety software packages provide a great tool to facilitate the development and the documentation of HACCP or Preventive Control Plans and pre-requisite programs. Users follow a step-by-step approach to build a compliant food safety management system using customizable SOPs and record templates.

When following international food safety practices, food manufacturers and importers must satisfy three key deliverables:

- First, they ensure that food safety data is documented for each lot of food, whether produced on-site or imported.

- Secondly, they verify that product specifications are consistently met and critical food safety processes followed.

- Thirdly, they address non-compliances by documenting the root causes of food deviations and corrective actions.

How Sirocco Consulting and Provision Are Helping Make Food Safer

Sirocco Food + Wine Consulting is currently collaborating with Provision Food Safety Software to offer a paperless version of the SQF Bundle. For a small annual subscription fee, the software which can be Cloud, SaaS or Web-based, allows the development of a complete and paperless food safety management system that is compliant with the GFSI benchmarked SQF scheme (Manufacturing module).

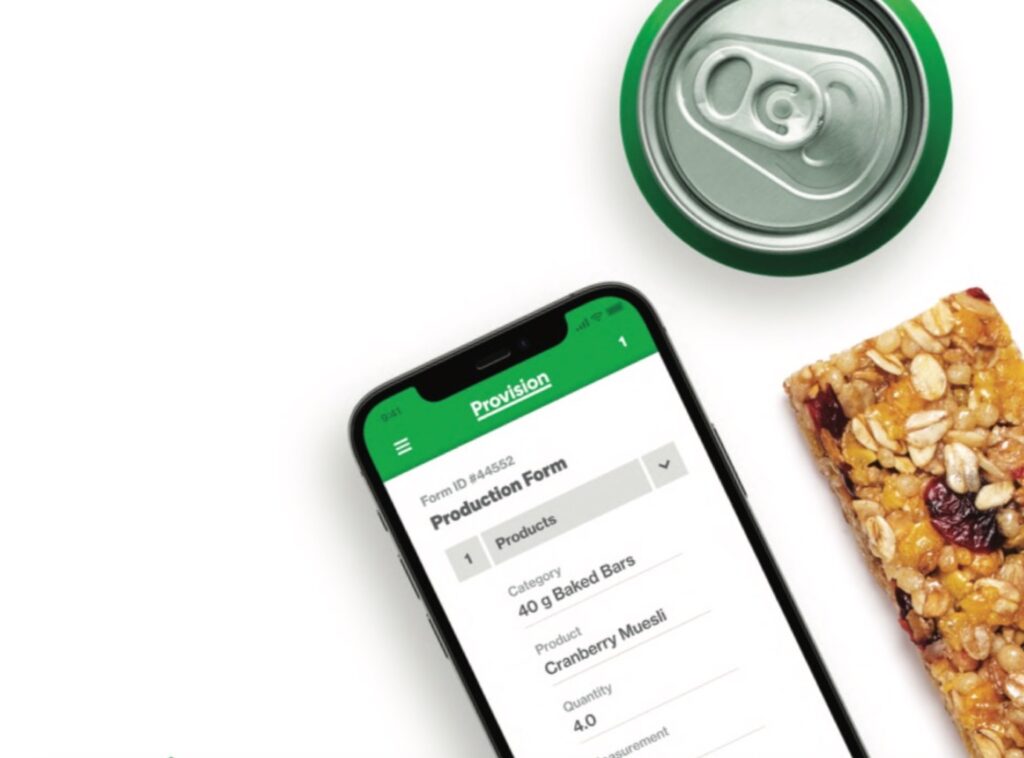

The value of Provision lies in the use of simple digital forms to automate food safety controls thereby advancing system verification through data trending and auditing activities. The software also connects all the food safety data (product testing, label reconciliations and reviews, equipment maintenance, sanitation and cleaning, pest control, water potability, allergen control) so that food businesses can quickly investigate cases of non-compliance and determine possible root causes.

With Provision, users spend less time chasing forms by using alerts and autofill. Mistakes are flagged and fixed promptly. They use electronic forms with rules to approve suppliers and perform supply chain verifications. Forms are used to perform product audits and facility inspections. Provision also makes mock recall and mass balance drills fast and easy by looking up products and raw materials by ID and pulling up associated food safety records.

Offering the ability to perform one-click traceability, schedule and assign tasks, Provision is the ideal paperless solution to reliably pass third-party audits. The software can be accessed by auditors and inspectors to complete remote audit activities. While the tool helps food businesses stay compliant (no tasks are missed and out-of-spec events trigger automatic corrective actions), it also helps instill a strong food safety culture. Employees are reminded of compliance targets and the need to complete critical compliance tasks using a facilitated work-flow.

It should be noted, however, that the software doesn’t automatically approve suppliers, perform a food safety hazard analysis for a given product category, or complete a mock recall. This is a tool for trained users: knowledge and understanding of HACCP, Preventive Controls, food safety risks and traceability are required to effectively use the software.

Get additional knowledge and understanding to help ensure your supply chain stays protected. Make your food safer with our help and get SQF certified affordably and easily!

REFERENCES:

(1) Zwietering, M. H., Schmid, S., Kirk, M., McMeekin, T. A., Ross, T., Baranyi, J., . . . Bowman, J. (2006). Information systems in food safety management. International Journal of Food Microbiology, 112(3), 181-194.

At Sirocco Consulting, we are SQF Experts and HACCP plan Writers. Book a free consultation with our experts to discuss the use of Provision Food safety software. Consult our blog for SQF related news and tips.